FINE—TUNING THE CLADDING

- Piccolo and the ROSE

- Apr 11, 2017

- 1 min read

Updated: Aug 1, 2019

The aluminium composite panelling was glued onto both sides and given the weekend to dry and cure before the back panel went on. As soon as that was secure, work started to take place on the sheet aluminium roof. This had been cut to precise specifications by a local steel fabricator who had also clamped the edge where there were two separate joins. We used 0.7 sheet aluminium, taking into consideration the weight and also the curved front forehead, which of course was well supported by the extra attention in framing.

Many hands certainly do make light work. I was always there to help whenever I wasn't being the 'gopher'. I had requested right from the beginning that whatever jobs I could do I wanted to be able to do, as I knew there would be many jobs that were certainly out of my expertise. We were a great team and managed to do the whole Reno without any ill feelings towards each other.

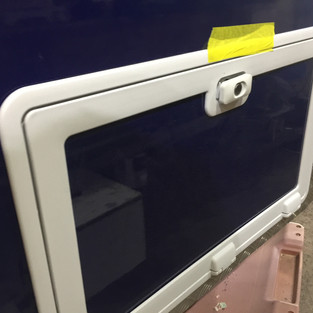

The 'boot' door was about to be fitted to give us access to the area beneath the bed. We were now able to finish off the checker-plate as well.

Comments